What is Film Faced Plywood

Composition of Film Faced Plywood:

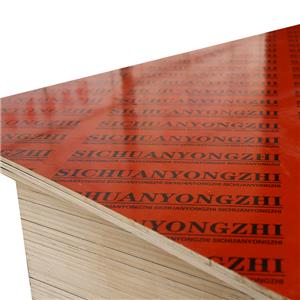

Film Faced Plywood is a type of plywood that features a specialized overlay on its surface. The core of the plywood is typically made of layers of wood veneers glued together with a strong adhesive. The overlay, which gives it the "film-faced" name, is a phenolic resin-impregnated paper or film. This film is usually applied to both sides of the plywood under high pressure and heat, creating a sturdy and resilient outer layer.

Characteristics of Film Faced Plywood:

Strength and Durability: The layered construction and the phenolic film make Film Faced Plywood exceptionally strong and durable. This strength is crucial in construction applications where the material is subjected to heavy loads and stress during concrete casting.

Smooth Surface Finish: The phenolic film provides a smooth surface finish to the plywood. This characteristic is vital when using FFP as formwork for concrete, as it ensures a polished and flawless appearance on the final concrete structure.

Water and Chemical Resistance: The phenolic film not only enhances the durability but also imparts water and chemical resistance to Film Faced Plywood. This makes it suitable for use in construction projects where exposure to moisture and various chemicals is inevitable.

Reusability: One notable advantage of Film Faced Plywood is its ability to be reused for multiple concrete casting cycles. Proper care and maintenance can extend the lifespan of FFP, making it a cost-effective choice over the long term.

Applications of Film Faced Plywood:

Film Faced Plywood finds extensive applications in the construction industry, primarily as formwork for concrete. Its versatility makes it suitable for a range of construction projects, including:

High-Rise Buildings: FFP is widely used in the construction of high-rise buildings, providing the necessary support for concrete casting in the creation of pillars, beams, and slabs.

Bridges and Infrastructure: The strength and durability of Film Faced Plywood make it ideal for infrastructure projects such as bridges, where it can withstand heavy loads and exposure to the elements.

Residential Construction: In residential construction, FFP is employed for creating foundations, walls, and other structural components, contributing to the overall stability of the building.

Environmental Considerations:

While Film Faced Plywood is a manufactured product, efforts have been made to source materials responsibly and adhere to environmental standards. Some manufacturers focus on using wood from sustainably managed forests and producing plywood with low formaldehyde emissions, addressing concerns related to environmental impact.

Conclusion:

In conclusion, Film Faced Plywood stands as a testament to the marriage of strength and versatility in construction materials. Its widespread use in formwork applications is a testament to its ability to meet the demanding requirements of modern construction projects. As the construction industry continues to evolve, Film Faced Plywood remains a reliable and indispensable ally, contributing to the durability and aesthetic appeal of structures worldwide.